Steps for working successfully with a Pipeline Manufacturer

Top Reasons to Choose a Trustworthy Pipeline Manufacturer for Your Framework Requirements

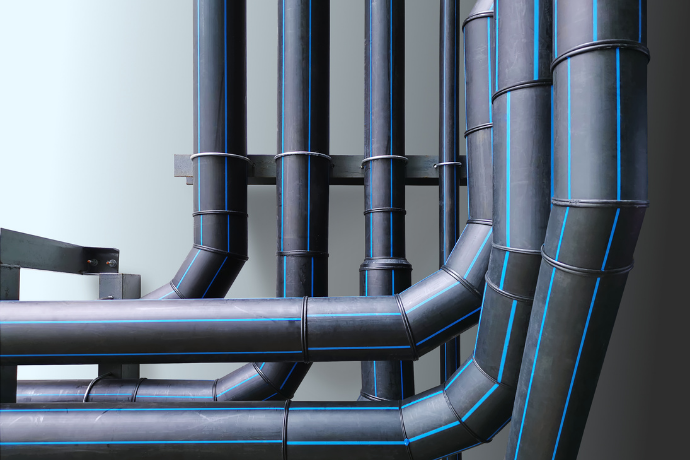

Choosing a trustworthy pipeline manufacturer is an essential choice that can substantially influence the success of your framework projects. Elements such as adherence to quality control procedures, conformity with governing criteria, and the accessibility of personalized remedies play an essential function in making certain safety and security and sturdiness. Furthermore, strong customer assistance and competitive rates might better boost the total value suggestion. As you take into consideration these components, it comes to be essential to understand exactly how they interconnect to form a foundation for your job's long-lasting practicality and performance. The effects of this choice might be extra extensive than at first perceived.

High Quality Guarantee and Standards

Assuring the honesty and dependability of pipeline manufacturing is critical, and this begins with strict quality assurance and adherence to sector requirements. A robust quality assurance program is essential to the production of pipelines that satisfy the strenuous demands of infrastructure applications. Producers need to carry out complete testing procedures, consisting of material assessment, weld integrity evaluations, and pressure screening, to guarantee that each pipeline segment can endure operational stresses.

Conformity with industry standards, such as those established forth by the American Society for Screening and Materials (ASTM) and the American Petroleum Institute (API), is essential in preserving high quality. These criteria include a variety of elements, including material requirements, producing procedures, and performance criteria, which work as a benchmark for examining pipeline quality.

Furthermore, continual tracking and analysis of manufacturing processes foster a culture of liability and improvement. By incorporating sophisticated modern technologies and approaches, such as Lean Production and 6 Sigma, pipeline producers can enhance their quality control efforts, lowering issues and guaranteeing peak efficiency. Ultimately, a dedication to quality control not only safeguards the honesty of the pipelines yet also infuses self-confidence in stakeholders, assuring that infrastructure requirements are satisfied properly and securely.

Boosted Safety And Security Attributes

Pipeline manufacturers are progressively focusing on improved security functions to deal with the dangers and intricacies connected with facilities jobs. In a period where security policies are becoming much more rigorous, manufacturers are purchasing innovative modern technologies and products developed to reduce risks connected to pipeline installation and procedure.

One noticeable safety and security function is the integration of leakage detection systems, which utilize sensing units and checking innovations to identify potential leakages before they escalate right into more significant concerns. These systems not just secure the environment yet likewise safeguard public wellness and property. HDPE Pipe Supplier. Furthermore, manufacturers are using advanced products that resist deterioration and tiredness, more minimizing the likelihood of disastrous failures

Numerous suppliers are executing strenuous screening protocols to assure that pipes can withstand extreme problems such as pressure surges and seismic tasks. Substantial training programs for personnel included in setup and upkeep enhance operational safety by making certain adherence to best techniques.

The adoption of automated control systems permits for real-time surveillance and action, supplying an added layer of security. By choosing a dependable pipeline manufacturer with an emphasis on enhanced security functions, stakeholders can considerably mitigate threats and ensure the honesty of their framework tasks.

Proven Toughness and Long Life

High-Quality Materials Used

Quality materials play a vital function in the manufacturing of reliable facilities services. A reliable pipeline manufacturer prioritizes making use of high-grade products to assure that their products can stand up to the rigors of functional demands and ecological stress factors (American Plastics LLC HDPE Pipeline Manufacturer). Materials such as state-of-the-art steel, polyethylene, and advanced composite materials are often picked for their premium stamina, deterioration resistance, and longevity

The choice of these materials significantly impacts the general toughness of pipeline systems, which are important for transferring various materials, consisting of water, gas, and oil. Top notch products not only enhance the mechanical buildings of the pipelines however also add to reduce maintenance prices and lower the probability of failures or leaks with time.

Moreover, the use of costs products contributes in following sector standards and policies, verifying that the framework can run properly under numerous problems. Inevitably, purchasing pipes made from top quality products translates to raised integrity and efficiency, making them a sensible selection for framework projects. Selecting a supplier devoted to using only the ideal products is an essential action in securing the integrity and performance of your facilities needs.

Strenuous Evaluating Requirements

Exactly how can producers assure the dependability and longevity of their pipeline systems? The response depends on the execution of extensive testing criteria throughout the manufacturing procedure. Reliable pipeline suppliers stick to strict quality control methods that encompass various stages of production. This includes first material inspection, in-process checks, and last product assessments to establish that every pipeline meets or surpasses industry requirements.

One of the critical elements of these screening requirements is the simulation of real-world problems. Makers subject their pipes to extreme stress, temperatures, and corrosive environments to assess their performance and resilience. Advanced strategies, such as non-destructive testing (NDT), are used to detect prospective imperfections that could jeopardize the integrity of the pipelines gradually.

Modification Options Available

Modification choices play an essential duty in boosting the performance and suitability of pipeline solutions when it comes to conference diverse facilities needs. Trustworthy pipeline producers understand that a person dimension does not fit all; for that reason, they offer customized remedies to deal with details job needs.

Modification choices may include variations in materials, diameters, and wall surface thicknesses, allowing clients to choose pipes that best match their operational conditions. As an example, suppliers usually provide choices for corrosion-resistant layers or specialized linings, guaranteeing longevity and reliability in challenging atmospheres. Furthermore, the capability to pick specific fittings and connection kinds boosts the versatility of the pipeline systems to varied formats and arrangements.

Suppliers may facilitate bespoke design services, which allow clients to work together on style aspects, ensuring that the pipeline integrates seamlessly with existing framework. This collective method not only enhances functionality but additionally enhances setup procedures.

Ultimately, by making use of personalization choices, firms can attain boosted performance, minimized upkeep costs, and boosted overall performance. Selecting a maker that prioritizes these choices is essential for any organization looking for to create a efficient and robust pipeline facilities.

Compliance With Rules

Guaranteeing conformity with guidelines is an essential element of pipeline manufacturing, as it safeguards both public security and environmental stability. Pipeline producers should follow a wide variety of neighborhood, national, and worldwide criteria, which regulate various elements of layout, materials, construction, and functional procedures. Conformity with these guidelines not only protects against legal effects but also improves the total reliability and safety and security of pipeline systems.

A reliable pipeline manufacturer will certainly remain upgraded on the most recent regulatory changes and warranty that their products satisfy or surpass these needs. This includes acquiring necessary accreditations and performing rigorous testing to confirm the integrity and durability of their pipelines. As an example, producers must follow criteria established by companies such as the American Society for Screening and Materials (ASTM) and the American National Specification Institute (ANSI), which establish standards for material top quality and safety and security.

Additionally, adherence to environmental laws is necessary to alleviate possible ecological influences. By choosing a supplier devoted to compliance, businesses can guarantee that their pipeline facilities not only meets functional demands however likewise adds to sustainable practices and community count on. This way, compliance works as a foundation for reliable and accountable facilities development.

Solid Client Assistance

Outstanding client assistance is a cornerstone of successful pipeline production, guaranteeing and cultivating long-term connections customer complete satisfaction. A trusted pipeline manufacturer comprehends that addressing customer demands is crucial throughout the job lifecycle, from initial appointment to post-installation support.

Solid customer assistance encompasses efficient communication, prompt actions, and expert support. Clients must expect a dedicated group that is easily available to attend to inquiries, give technological assistance, and troubleshoot problems as they arise. This level of interaction not just improves the client experience yet likewise alleviates potential dangers connected with pipeline jobs.

In a competitive landscape, strong client support separates a trustworthy pipeline manufacturer from its equivalents. By choosing a manufacturer that prioritizes customer relationships, stakeholders can assure that their infrastructure demands are consulted with professionalism and care, eventually resulting in effective job outcomes.

Affordable Rates and Worth

Affordable rates is important for any pipeline manufacturer intending to give affordable services to framework demands. By guaranteeing that products supply long-lasting investment value, business can cultivate count on and loyalty amongst their clients. This strategic technique not just enhances consumer contentment but also placements Check This Out makers as leaders in an affordable market.

Cost-efficient Solutions

In today's competitive market, many companies look for cost-efficient services that stabilize quality and cost. Selecting a trusted pipeline manufacturer is critical for attaining this goal. A maker that prioritizes affordable rates can offer substantial savings without endangering on the honesty or performance of their products.

Cost-effective remedies are not just concerning lower prices; they encompass the total value offered. A reputable manufacturer assurances that their pipes fulfill market standards and regulative needs, which can stop costly rework or downtime in the future. Moreover, by spending in top notch materials and progressed manufacturing processes, these firms can provide items with improved resilience and decreased maintenance prices.

Additionally, a trustworthy manufacturer typically has actually developed relationships with suppliers, enabling them to source products much more efficiently and pass those cost savings on their consumers. This tactical benefit can lead to a better cost point for projects, making it easier for organizations to handle their budget plans efficiently.

Ultimately, picking a pipeline manufacturer that offers cost-effective options makes it possible for companies to maximize their facilities financial investments while safeguarding long-lasting functional success. This thoughtful strategy settings firms to prosper in a progressively affordable landscape.

Long-Term Investment Worth

Buying high-grade pipeline solutions not only ensures prompt functionality yet likewise adds to lasting value for companies. When selecting a trustworthy pipeline manufacturer, companies take advantage of affordable pricing that reflects truth well worth of effective and sturdy products. These producers prioritize high quality products and cutting-edge designs, making certain that the pipelines endure the test of time and decrease the requirement for constant replacements or repair work.

A reliable manufacturer usually gives extensive warranties and assistance services, even more boosting the overall value of the investment. By choosing pipes engineered for long life, companies can reduce operational interruptions and connected costs, causing greater performance over time.

Additionally, with the best manufacturer, companies can attain expense financial savings through boosted energy effectiveness and reduced upkeep needs. This translates right into lower operational expenses, allowing for better allowance of resources towards various other vital facilities tasks. Eventually, purchasing trustworthy pipeline remedies is not simply a purchase; it is a calculated choice that pays dividends with time, reinforcing the organization's commitment to sustainability and functional excellence.

Regularly Asked Concerns

What Products Are Generally Used in Pipeline Production?

Pipeline making generally makes use of materials such as steel, ductile iron, polyethylene, and PVC (Pipeline Manufacturer). These products are chosen for their sturdiness, resistance to corrosion, and suitability for different applications, making certain reliable and efficient transport of liquids

How Can I Confirm a Maker's Credibility?

To validate a supplier's track record, study online evaluations, look for endorsements from previous clients, check industry certifications, and speak with relevant expert associations. Additionally, examine their background of job shipment and adherence to safety and security and top quality criteria.

What Is the Average Lead Time for Pipeline Distribution?

The average preparation for pipeline shipment generally varies from six to twelve weeks, relying on aspects such as material specifications, making ability, and order volume - American Plastics LLC HDPE Pipeline Manufacturer. Timely communication with suppliers can give extra exact quotes

Exist Warranties Readily Available for Pipeline Products?

Yes, several credible pipeline manufacturers supply service warranties on their items. These guarantees commonly cover issues in materials and handiwork, ensuring that customers get long lasting and trustworthy solutions for their framework jobs, thus enhancing total project long life.

Can I Visit the Manufacturing Center Before Positioning an Order?

Yes, many trustworthy pipeline suppliers motivate visits to their centers. This enables prospective customers to assess production standards, quality assurance procedures, and overall operations, fostering transparency and self-confidence prior to making significant getting choices.

Picking a dependable pipeline manufacturer is a crucial decision that can greatly influence the success of your facilities projects. Pipeline producers are increasingly prioritizing boosted safety and security functions to attend to the complexities and dangers linked with infrastructure jobs. A respectable pipeline manufacturer prioritizes the use of premium materials to assure that their items can endure the roughness of operational demands and environmental stress factors. By on a regular basis upgrading screening methods and incorporating ingenious innovations, manufacturers can assure that their pipes are developed to last, providing important facilities that holds up against the examination of time. Pipeline suppliers need to stick to a plethora of local, national, and global standards, which regulate various aspects of layout, materials, building, and functional methods.